|

Overview: Hydac 2600R020BN4HC hydraulic oil filter is mainly used to remove solid particles, moisture and pollutants in hydraulic oil, ensure system cleanliness, and extend the service life of hydraulic pumps, valves and actuators. 2600R020BN4HC hydraulic oil filter is widely used in industrial hydraulic systems, mobile hydraulic equipment and high-precision filtration occasions.

Basic Parameters: • Model: 2600R020BN4HC • Filter accuracy: 20μm • Working temperature: -20℃~150℃ • Life Cycle: 2500h~4000h • Maximum working pressure difference: 2.6MPa~32MPa • Filter material: Glass fiber • Filter type: Folding hydraulic oil filter element • Applicable media: General hydraulic oil, lubricating oil • Structural features: Folding design, with spiral center tube, oil-resistant sealing ring • Purpose: Filter out metal powder, mechanical impurities, dust and other pollutants in hydraulic oil • Application Scope: Hydraulic system oil circuit (suction circuit, pressure circuit, return circuit, etc.)

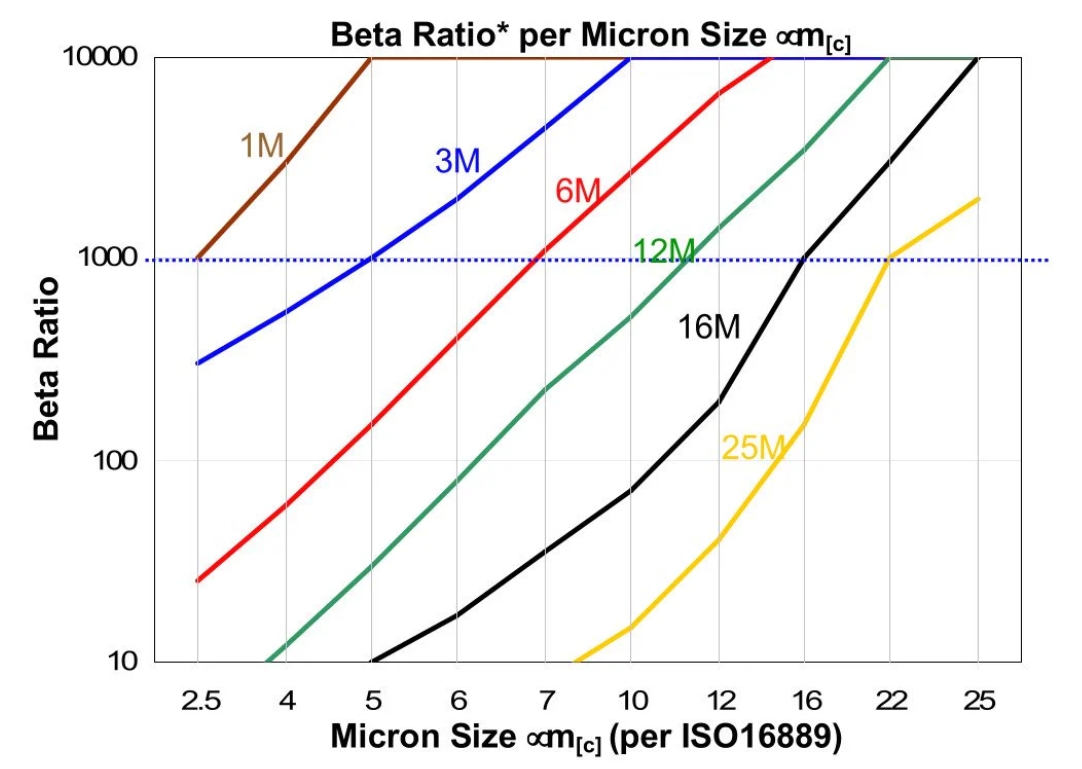

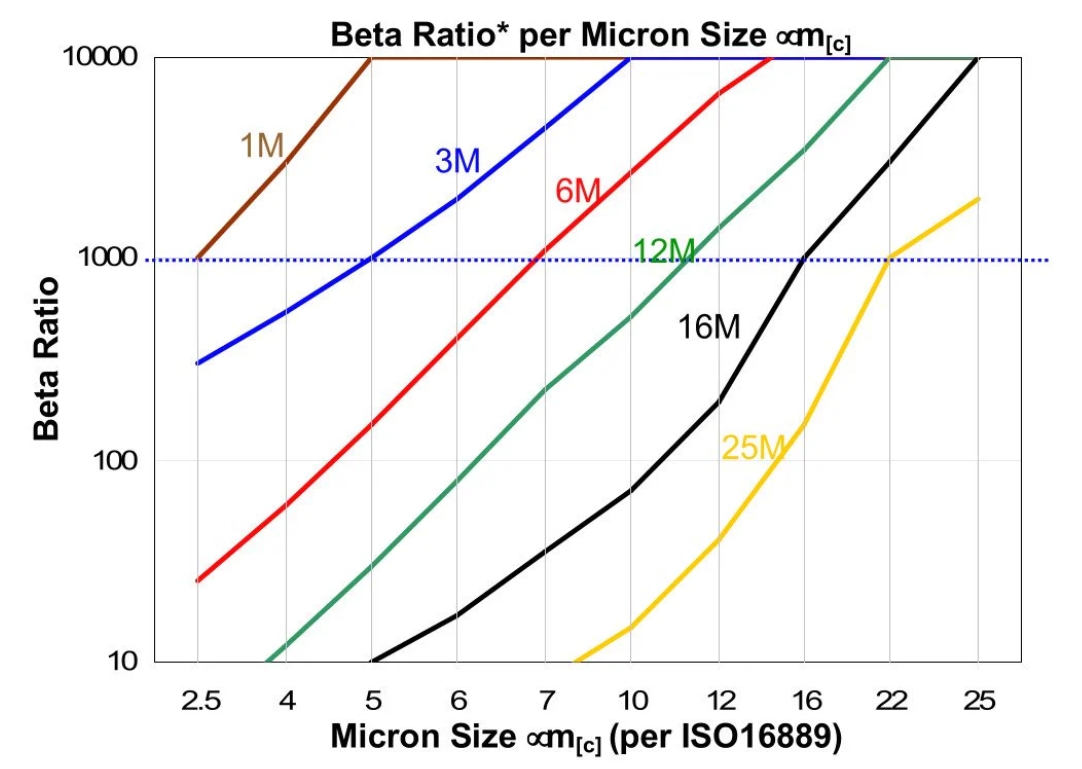

Quality advantage: Our 2600R020BN4HC hydraulic filter is certified Beta rated, providing superior contamination control. Their superior Beta X=1000 rating means that for every 1,000 x-sized particles in the oil, an average of only one will pass through, ensuring maximum system cleanliness.

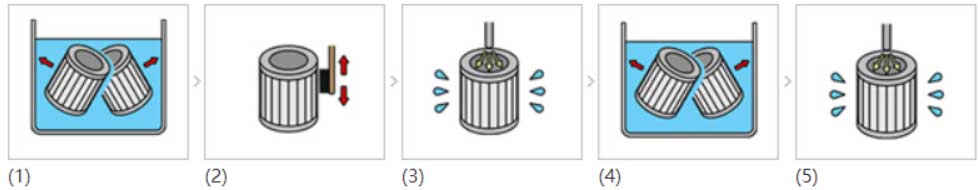

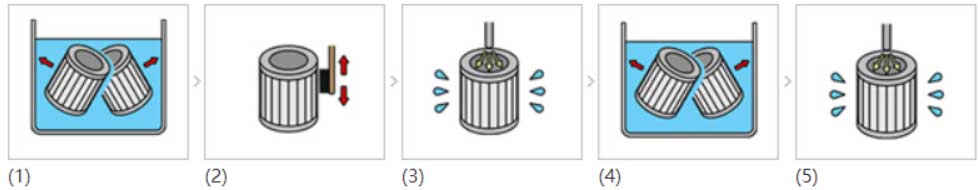

2600R020BN4HC Oil Filter Clean: 2600R020BN4HC hydraulic oil filter is a folded glass fiber filter material, which increases the filtration area and dirt holding capacity. Contains bypass valve (low pressure series): automatically opens when the filter element is blocked to protect the system from continuous operation  | (1) Dip the filter element in light oil and rotate thoroughly. | (2)Clean off dirt by scrubbing the element with a brush parallel to the pleats. | (3)Clean off dirt with an air spray gun. | (4)Rinse well. | (5)Dry using an air spray gun. |

Application: ✔️ Engineering machinery: impurity filtration in hydraulic systems of excavators and cranes ✔️ Energy and power: steam turbine lubrication system, nuclear power feed pump oil purification ✔️ Metallurgy and petrochemicals: rolling mill hydraulic oil cleaning, oil field water injection filtration ✔️ Transportation: ship hydraulics, railway internal combustion engine oil circuit maintenance

Test standards: 2600R020BN4HC hydraulic filter is rigorously tested before shipment to ensure compliance with international standards. Our comprehensive quality control process includes: ISO 2941 Collapse & Burst Resistant ISO 2942 Fabrication & Integrity Test ISO 2943 Material Compatibility with Fluids ISO 3724 Flow Fatigue Characteristics ISO 3968 Pressure Drop vs. Flow Rate ISO 16889 Multi-pass Performance Testing

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration