|

Introduction: Our manufacture CAA56-5 coalescer is made of composite materials with hydrophilic properties through a variety of special processes. It can not only remove emulsified water in the medium through demulsification and coalescence, but also filter out mechanical impurities in the medium. CAA56-5 belongs to the coalescing separator category, coalescing and separating into larger water droplets to achieve further purification of the medium.

Performance Features: • Tested and qualified • pH range from 5 to 9 • Ultra-fine solids removal • Maximum water coalescence • Balanced cartridge flow characteristics • Withstands in excess of 75 psi differential pressure • Multi-layered media for increased solids holding capacity • Recommended maximum operating temperature: 240°F (115℃)

Material: We make CAA56-5 aviation fuel coalescer using glass fiber coalescing filter elements made of high density gradient glass fiber. CAA56-5 fuel coalescer is designed as a one-piece one-piece tube construction to reduce damage and leaks. The surface of the filter element has been treated with hydrophobicity and oleophobicity to meet the requirements of various precision levels. • The composite glass fiber and fold medium coalescers mainly remove particles from high surface area fold cores. • All glassfiber media aggregator combines deep particle filtration with deep coalescence structure. • The all-glass fiber design has a continuous thinner dielectric layer to achieve deep filtration of particles.

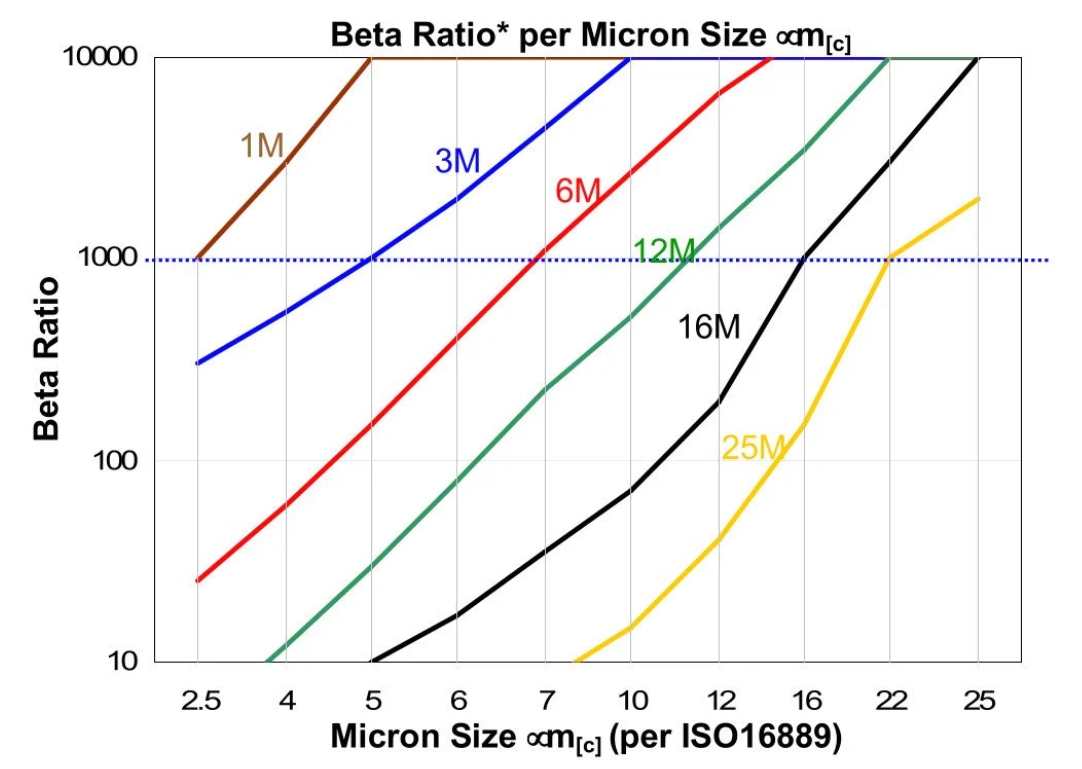

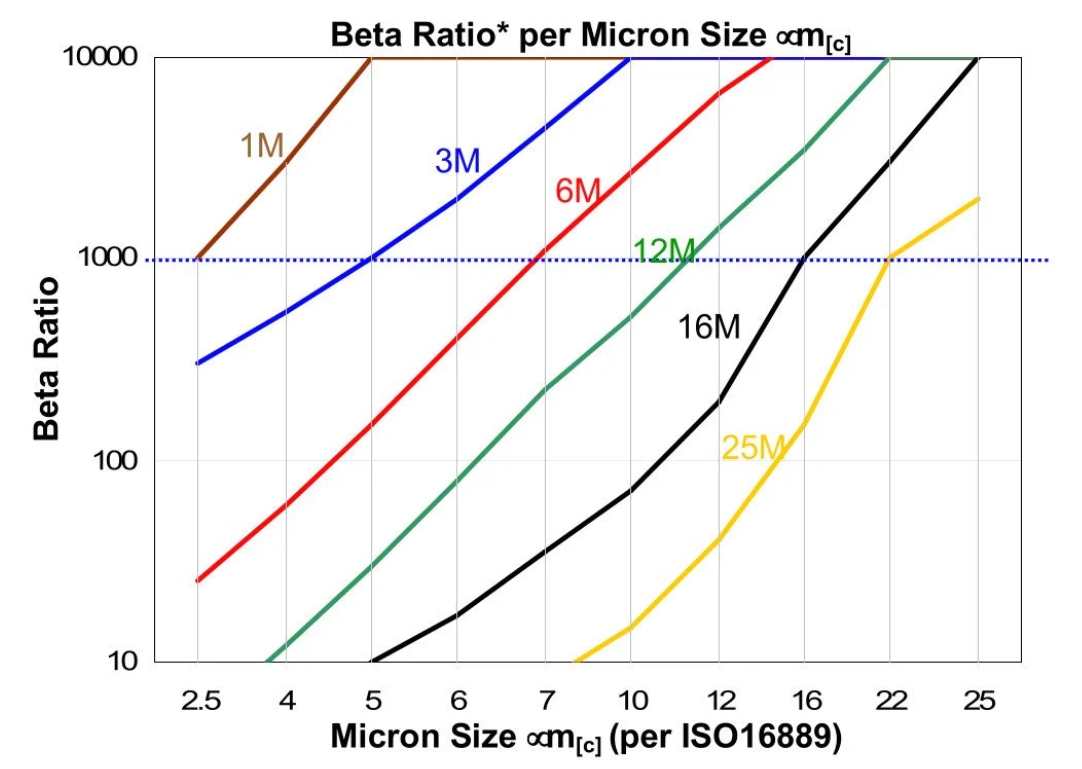

CAA56-5 Filter Performance: The CAA56-5 coalescing filter element material is usually made of polyester fiber synthetic material and has good compatibility with various fluids. The filter element is spirally wound with a multi-layer structure. Each layer uses fibers with different properties. By controlling the shape, size, thickness, density and other parameters of the fibers in each layer, the expected filtration accuracy can be achieved. The CAA56-5 coalescing filter element is made of surface-treated polyester fiber or glass fiber as the binding medium. Specially designed filter material gives the filter media good coalescing properties. We make CAA56-5 facet coalescer replaces the filter element with Beta grade. Excellent filtration performance. The Beta X = 1000 number means that for every 1000 x size particles in the fluid, on average only one particle will pass through the filter.

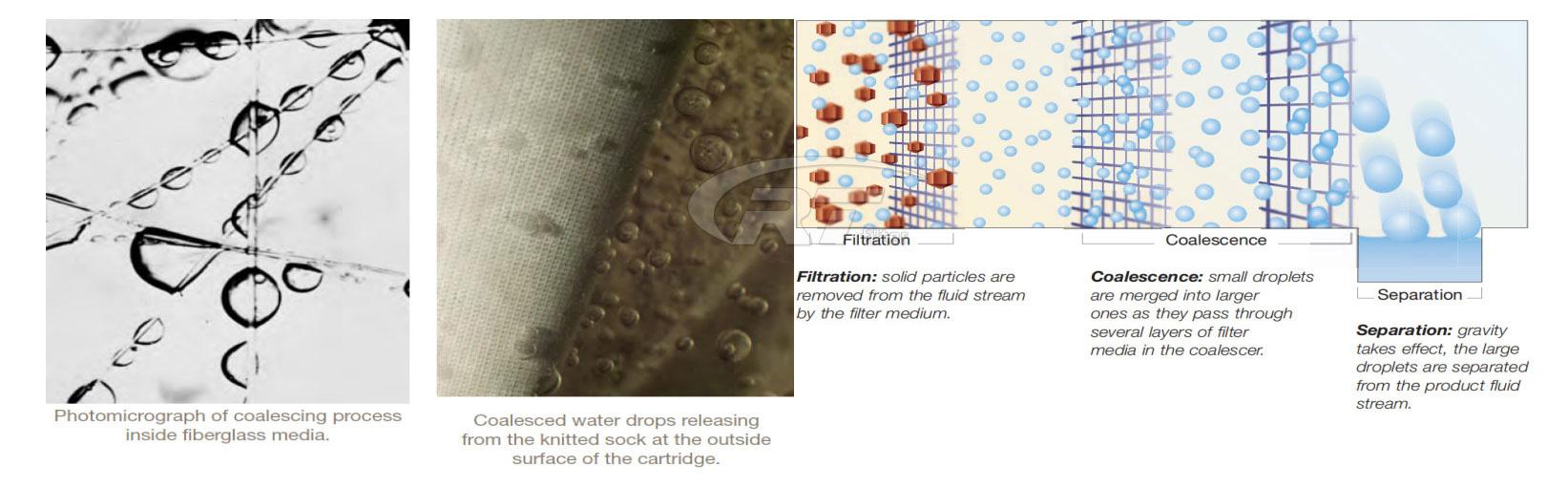

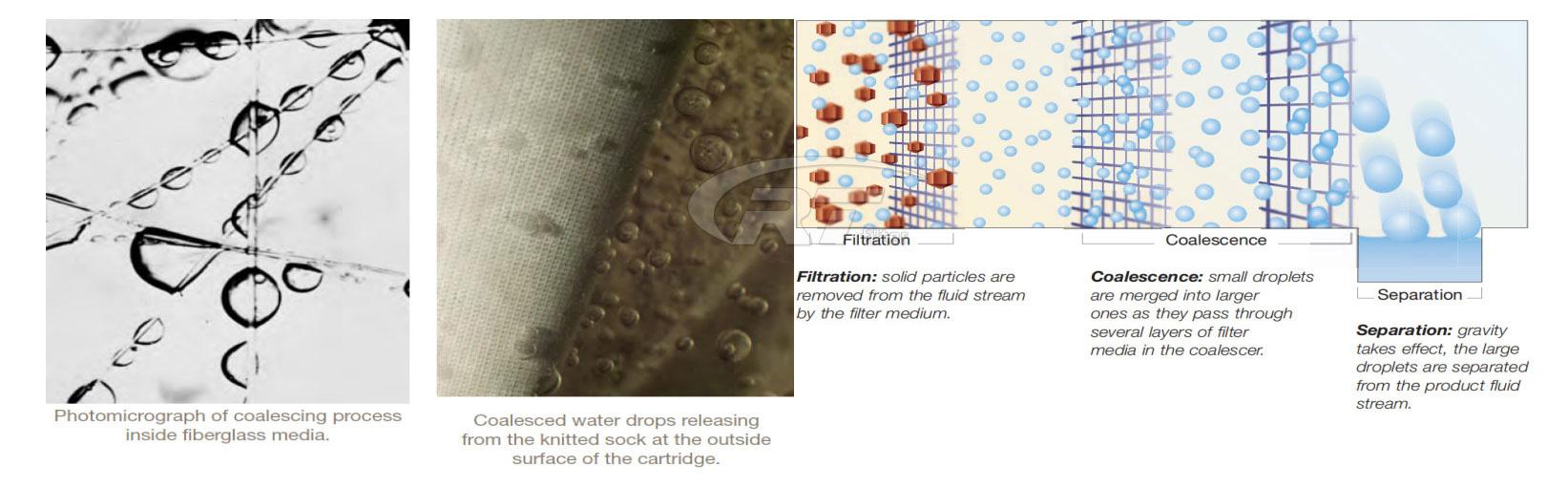

Work principle: Droplets of water, oil, and other liquids are captured by microfibers inside the coalescer. The product material consists of micron-sized fibers that form zigzag channels of airflow, forcing solid particles and liquid mist droplets to undergo three processes: inertial collision, diffusion interception, and direct interception. Through the action of the above filtration process, microfibers capture them. The surface tension of the liquid causes small droplets to coalesse into larger droplets. And through the action of gravity, large droplets will settle to the bottom of the container.

Test standards: Before delivery, Our manufactured CAA56-5 aviation fuel coalescer will be tested and follow the standards: ISO 2941 Collapse & Burst Resistant ISO 2942 Fabrication & Integrity Test ISO 2943 Material Compatibility with Fluids ISO 3724 Flow Fatigue Characteristics ISO 3968 Pressure Drop vs. Flow Rate ISO 16889 Multi-pass Performance Testing

Our factory also offers a full range of replacement filter elements: Parker & Velcon PECO & Facet Faudi Pall Other types are available on request

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration