|

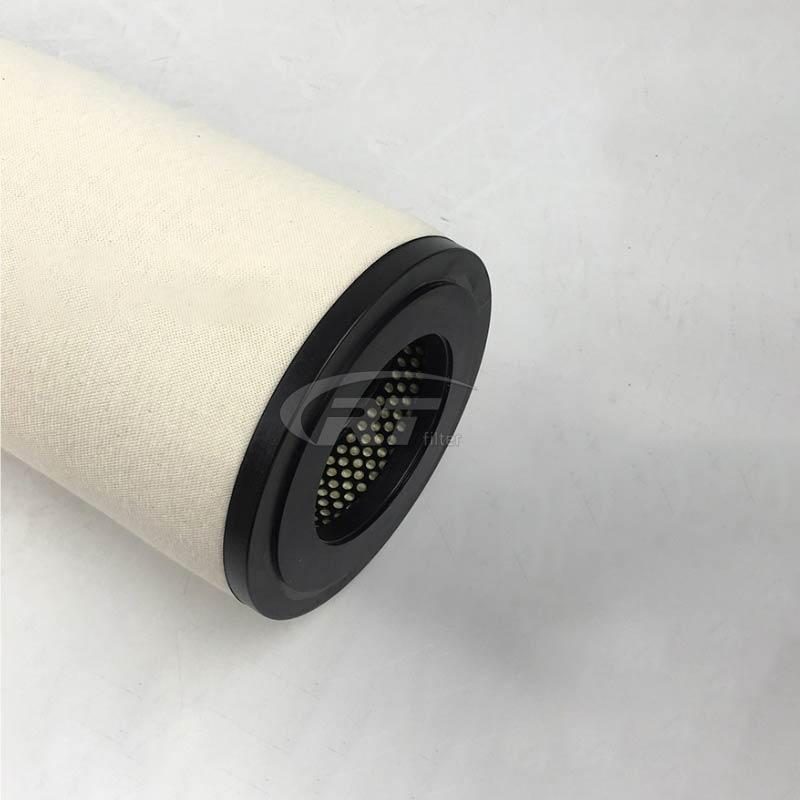

Introduction: HC628-01-CSP HILLIARD HILCO separator filter main function separate oil-water mixtures, suspensions, emulsions, etc. Filter out solid impurities and coalesce to remove moisture from oil/oil gas. Prevents clogging of orifices in pneumatic controllers and reduces gas engine fouling. The coalescing material is consolidated through special resin and technology, and is oil and water resistant. It is suitable for high flow and strong pressure pulsation, and the joints of the filter material are strong and tight.

Performance Features: • Large dirt holding capacity prevents clogging of the orifices in the pneumatic controller. • Multi-layer composite structure filter paper with high filtration accuracy. • Reduces fouling of gas engines and instrument pneumatic equipment. • High flow density, reducing scaling tendency and pressure drop. • High area pleated fiberglass media for good coalescence.

Material: We make HC628-01-CSP separator filter using high density gradient glass fiber. HC628-01-CSP fuel separator is designed as a one-piece one-piece tube construction to reduce damage and leaks. The surface of the filter element has been treated with hydrophobicity and oleophobicity to meet the requirements of various precision levels. • The composite glass fiber and fold medium coalescers mainly remove particles from high surface area fold cores. • All glassfiber media aggregator combines deep particle filtration with deep coalescence structure. • The all-glass fiber design has a continuous thinner dielectric layer to achieve deep filtration of particles.

Filter Performance: We make HC628-01-CSP oi gas coalescing separator filter material is usually made of polyester fiber synthetic material and has good compatibility with various fluids. The filter element is spirally wound with a multi-layer structure. Each layer uses fibers with different properties. By controlling the shape, size, thickness, density and other parameters of the fibers in each layer, the expected filtration accuracy can be achieved. The HC628-01-CSP coalescing separator filter element is made of surface-treated polyester fiber or glass fiber as the binding medium. Specially designed filter material gives the filter media good coalescing properties. Our manufactured HC628-01-CSP hilliard hilco oil gas separator replaces the filter element with Beta grade. Excellent filtration performance. The Beta X = 1000 number means that for every 1000 x size particles in the fluid, on average only one particle will pass through the filter.

Work principle: HC628-01-CSP coalescing separator filter element processes in the system: solid-liquid separation-emulsification-coalescence-separation-adsorption. In the oil dehydration system, after the oil flows into the separator, it first flows through the coalescing filter element to filter out solid impurities and coalesce very fine water. The coalesced water droplets are separated from the oil by their own weight and settle in the oil pan. At the same time, the materials used in HC628-01-CSP have good lipophilicity and hydrophobicity, and water is further separated. Finally, clean, water-free oil flows out of the coalescer.

Application: • Liquefied petroleum gas, petroleum tar, benzene, toluene, xylene, cumene, polypropylene, etc. • Cycloethane, isopropanol, cycloethanol, cycloethanone, etc. • Jet fuel, gasoline, kerosene, diesel. • Low viscosity gear oil such as turbine oil, lubricating oil, hydraulic oil, etc. • Other hydrocarbons.

Test Standards: Before delivery, Our manufactured HC628-01-CSP coalescing separator filter will be tested and follow the standards: ISO 2941 ------ Resistance to collapse and bursting ISO 2942 ------ Manufacturing and Integrity Testing ISO 2943 ------ Compatibility of materials and fluids ISO 3723 ------ End load test method ISO 3724 ------ Flow fatigue properties ISO 3968 ------ Pressure drop and flow rate ISO 4572 ------ Multiple pass performance tests

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration