|

Description: The modernization of hydraulic technology has led to the performance parameters of the hydraulic system tending towards ultra-high pressure,large flow and high precision.In order to ensure the performance and reliability of the hydraulic system,the cleanliness of the oil is required to be higher and higher. The oil purifier developed by Our factory can not only be used as a special equipment for injecting new oil into the hydraulic system,but also can be used as a special equipment for regularly filtering pollutants in the system medium.It can help you better deal with the pollution of the hydraulic system and prolong the service life.The service life of hydraulic components ensures the normal operation of the system. The LUC,LUCA,LUCB series oil filter trolleys replacement produced by our company not only have reliable performance,compact structure,beautiful appearance,convenient maintenance and use,but also have the advantages of high precision and low noise.According to different needs,you can freely choose among 3, 5, 10, 20, 30um,and you only need to replace the filter element with different filtration precision to achieve the filtration effect of different precision.All technical indicators of the oil have no effect.

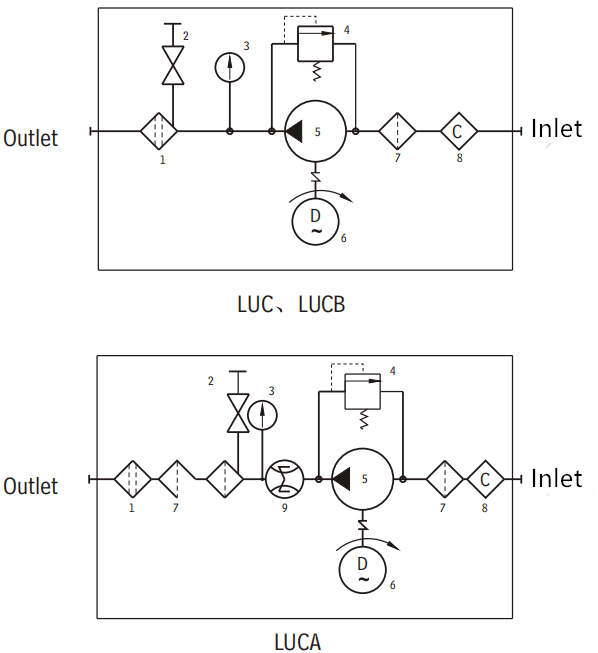

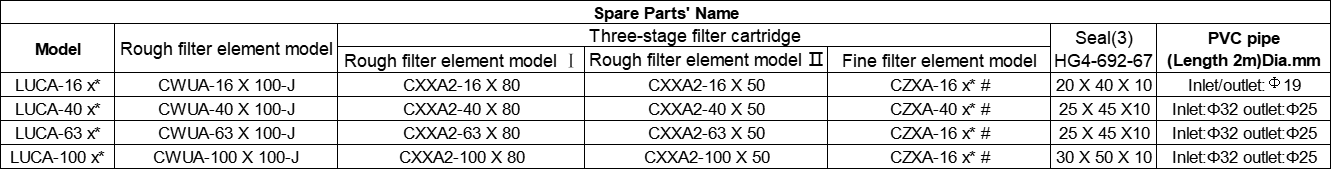

DRAWING OF OIL CIRCUTI :

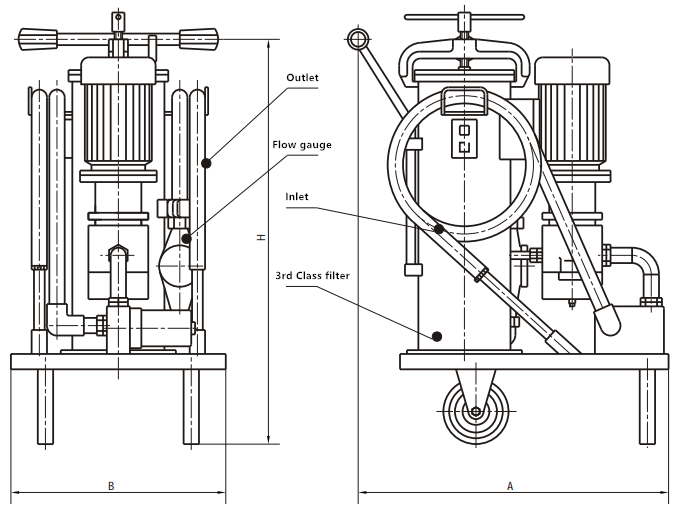

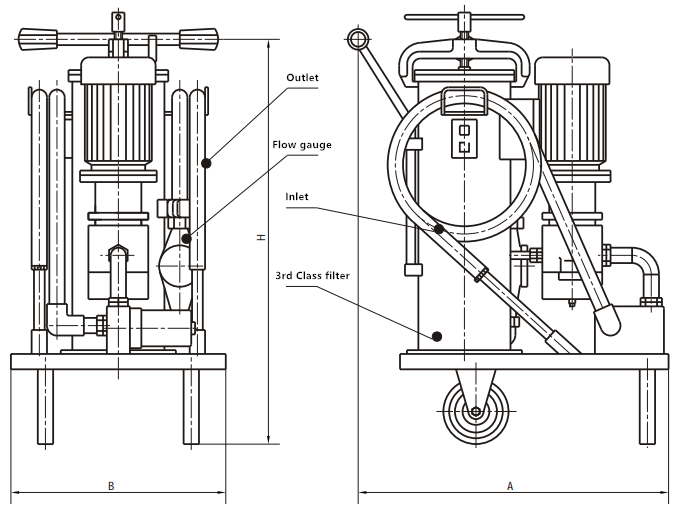

1. Fine filter 2. Discharge valve 3. Pressure gauge 4. Safety valve 5. Pump 6. Motor 7. Rough filter 8. Magnetic filter 9. Flow gauge

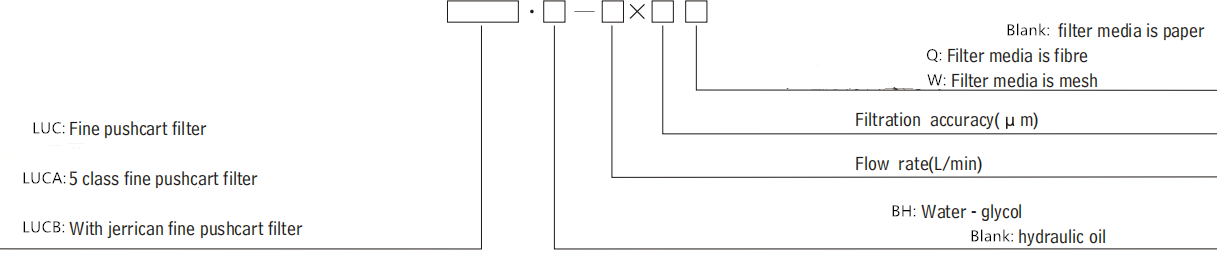

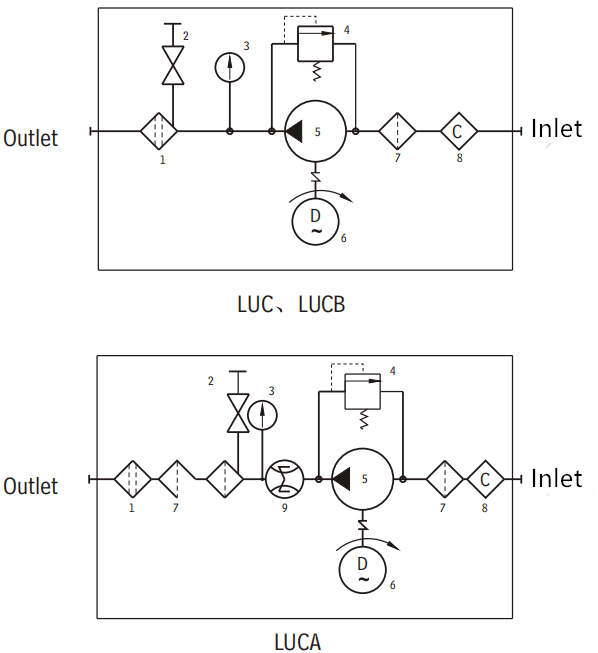

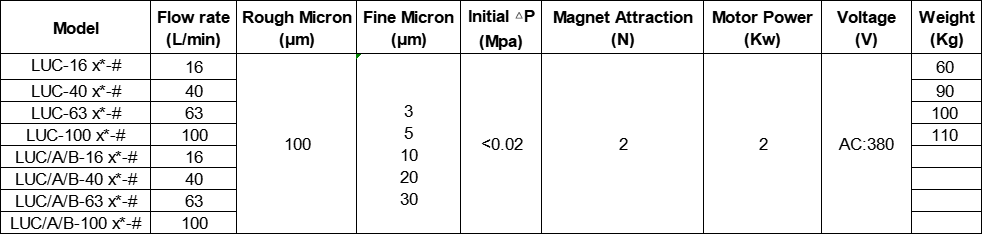

Model Code:  Technical Data:

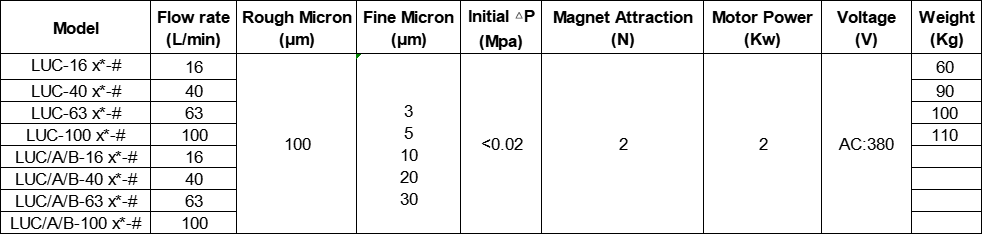

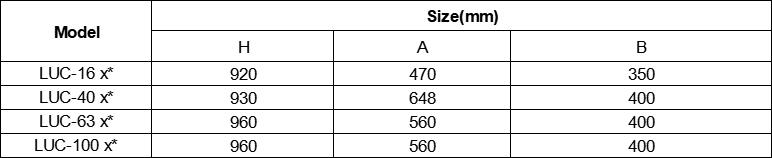

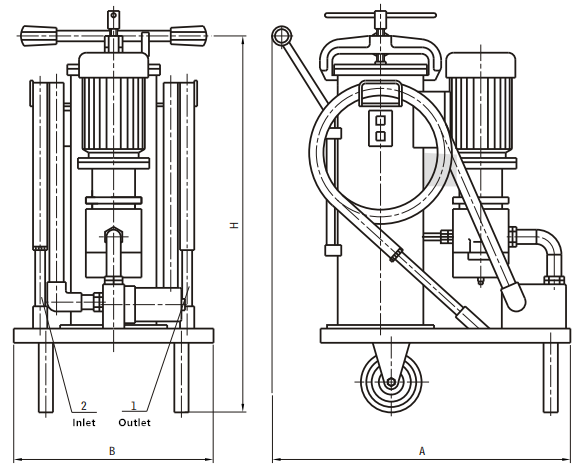

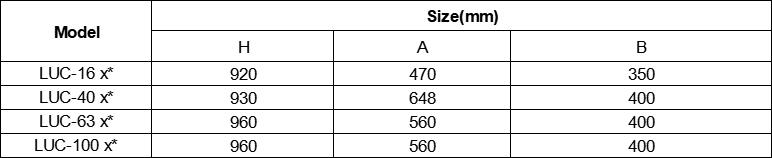

Sizes: (1). LUC Series:

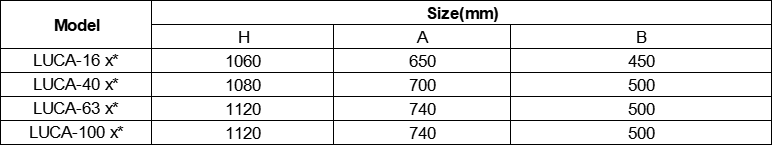

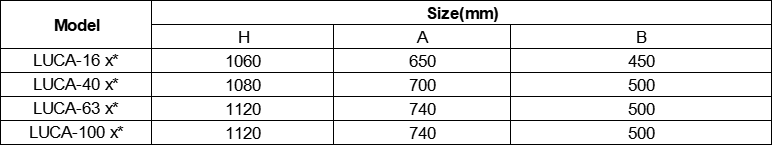

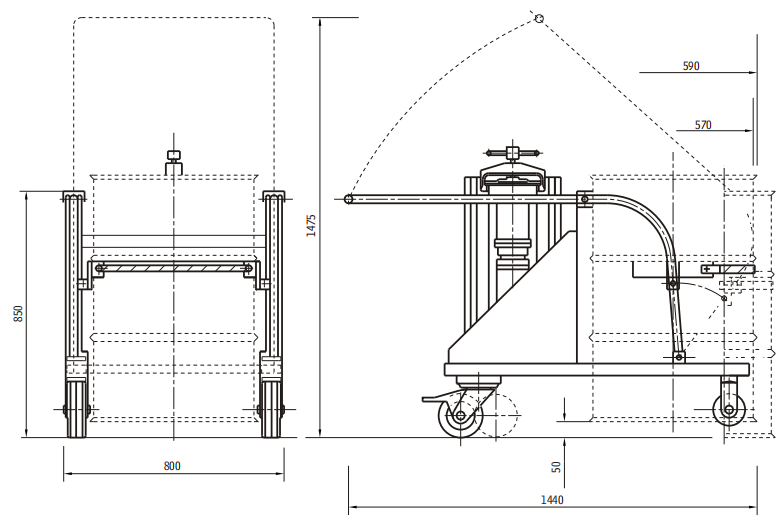

(2). LUCA Series:

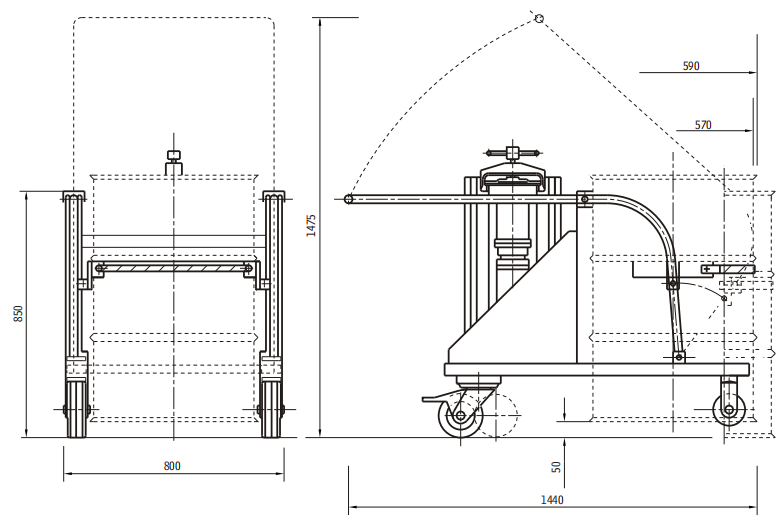

LUCB Series

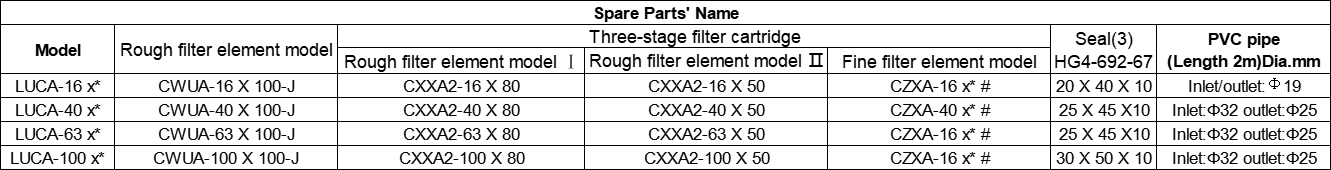

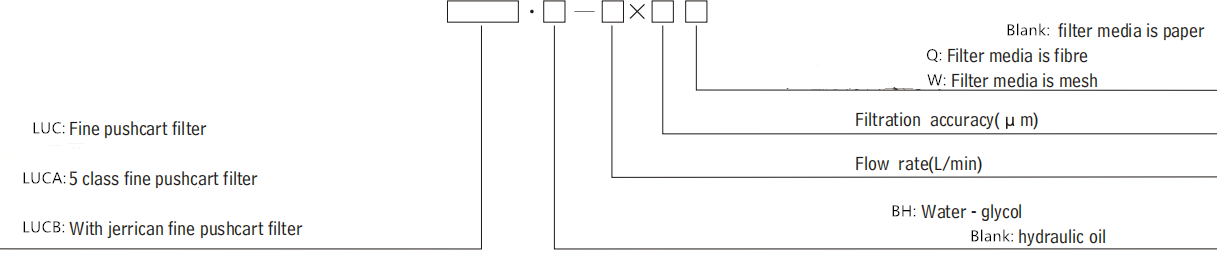

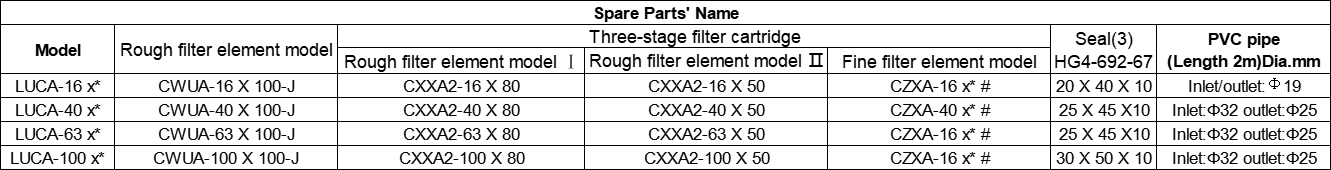

Spare Parts:

Note: (1). The *is filtration accuracy. If the fluid is water-glycol,flow rate 63L/min filtration accuracy 5 m, filter media is paper, the model of pushcart filter is LUC-BH-63 5 or LUCA-BH-63 x5,the model of fine filter element is CZX-BH-63 5 or CZXA-BH-63 5. s filter media.Omit if Filter media is paper; Q: Filter media is fibre; w: Filter media is mesh. (2). To ensure the flow of pushcart filter,the customer should select the inside diameter of the hose according to the above table form,and not flatten the hose when working.The height of suction oil should less than 500mm.The suction pipe can not be prolonged;he return pipe can not be longer than 8m. (3). It means seal of pump shaft.

Test standards: ISO 2941 Collapse & Burst Resistant ISO 2942 Fabrication & Integrity Test ISO 2943 Material Compatibility with Fluids ISO 3724 Flow Fatigue Characteristics ISO 3968 Pressure Drop vs. Flow Rate ISO 16889 Multi-pass Performance Testing

How to make maintenance: (1). Avoiding the possible counter rotation of the oil pump while starting the machine,otherwise it may lead to the out blown of the axle seal and entering of air. (2). Air might be introduced into the machine during the operation and affect the oil flow.To ensure the rated flow and normal operation of the fine filter element,the discharge valve should be opened in time to release the air until oil can be seen at the outlet of the discharge valve,then close the discharge valve closed. (3). After a certain period of peration,coarse cleaner could be gradually contaminated and noise of pump might occur, you should stop the machine in order to clean the filter element. (4). Dirt might stick to the elements of fine filter,causing a rise of the pressure in the filter bowl. When the pressure hits 0.4MPa,the elements should be the changed in time. (5). The suction and oil outlet tube should always be kept clean. (6). Should the pushcart filter fail to pump oil,please check: a. The rotating direction of the pump; b.Whether the sealings between the tank and oil inlet are properly;the oil inlet is above the oil surface or oil runs out; c. If the elements of rough filter are stuck. (7). If the oil flow distinctly reduced,please check: a. Whether the elements of rough and fine filters are stuck with filth. b. Whether an out blown of the axle seal has occurred due to wear or counter rotation. (8). If a sudden pressure drop occurs,please check whether the elements of fine filter have been damaged.

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration