1.Brief introductionWe manufacture the PFC 8300-50-YV high efficiency oil purifier replacement and adopts new environmentally friendly filter elements,which can perform high efficiency filtration of solid particles in a variety of liquid media on various occasions.

More Related Filters: PFC8300-100-H-LZ-YV PFC8314-50-H-LZ-YV PFC8314-100-H-LZ-YV PFC8314-150-H-LZ-YV PFC8314-400-H-LZ-YV PFC8314U-100H-LZ-YV PFC8300-50-H-OR-YV PFC8300-100-H-OR-YV PFC8300-50-H-OM-YV

1.1 Features of PFC 8300-50-YV inside filter elements: (1). Use spiral tape to strengthen the support. Ensure the filter material is stable. LZ filter material is made of adsorbable water-based resin material. (2). Filtration of solid pollutants is fast and efficient (βx(c)≥1000) (3). It adopts a gradient pore structure that gradually shrinks from the surface to the inside and along the flow direction to intercept pollution particles of different sizes in layers to achieve volumetric fouling, thus greatly improving the service life. (4). The filter material is made of patented fiber and resin through a unique process. It has a fixed pore structure and the filter material does not fall off. The intercepted pollution particles will not cause "leakage" due to pressure difference and flow pulsation.

1.2 Features of PFC series oil purifier: (1). Add oil collection pan and oil pipe fixtures. reduce environmental pollution.The oil pump has a relief valve. (2). Sound and light pressure difference alarm prompts to replace the filter element.The oil suction port primary filter protects the oil pump. (3). Lock the differential pressure alarm. Prevent false alarms during cold start.The filter has a bypass valve to avoid system interruption. (4). Oil outlet diffuser to prevent air from mixing into the fuel tank.Universal wheels make movement more flexible and convenient. (5). Motor phase loss and phase error protection.

1.3 Function: (1). Oil pan and tubing fixture:can reduce the environmental pollution to site environment. (2). Inlet coarse filter:protect oil pump and extend the life of filter element. (3). Default phase & fault-phase protection:prevent motor reversal or lack of phase operation,which can protect oil pump and filter core. (4). Universal front wheel:reach more flexible and portable move. (5). Sound light alarm:prompt to change the filter element. (6). Outlet diffuser:control the return flow direction and flow rate to prevent swirl of air to go into the tank.

The PFC8300-50YV oil purifier can not only filter lubricants such as mineral oil, water glycol, emulsion, HWBF, but also filter corrosive oils such as phosphonate refractory hydraulic oil, and can also be used to fuel your system, but also to reach the bypass cycle filtration of the system tank.

2.Operation: (1). System connection: (a). Bypass circulating filtration of system tank Use an oil tube to connect the bottom of oil tank and the inlet of the oil purifier, then use another oil tube to connect the outlet of the oil purifier and the inlet of the oil tank. (b). Filling the oil for your system Use an oil tube to connect the oil storage tank and the inlet of the oil purifier, then use another oil tube to connect the outlet of the oil purifier and the oil tank which needs to be filled. Note: please guarantee the inlet and outlet of the oil purifier are connected separately with two sides of the oil tank.

(2). Switch on plug the power plug into the socket,turn on the power (380V * 3φ/ 50HZ),the power indicator light (red light) is lit. (3). System startup open the inlet and outlet ball valves,press start button,the work indicator light (green light) is lit,the oil purifier starts to work. Note: the gas inside the system should be emptied at each start.(check part of element changing)

(4). System shutdown pressure stop button, the work indicator light (green light) is off, the oil purifier stop working. (5). System emptying remove the outlet oil tube from the liquid level, press start button to pump out the residual oil in the machine and tube. (6). Colse the inlet and outlet ball valves put the inlet and outlet oil hose (mouth of pipe is gadarene) in pipe clamp. (7). Spin the plug under the lacquer tray can release the residual oil that is collected in the lacquer tray. (When the oil purifier is working,if the element’s pressure difference exceeds the set point,the element alarm light is lit and you can hear buzzing;if the input power’s phase sequence is inversely connected or the input power is lack of phase,phase sequence indicator light is lit.)

3.Maintenance and service: This oil purifier is made of high quality raw material and components and parts,which can guarantee the high quality of the whole machine.In order to guarantee this PFC oil purifier’s excellent performance to be reached sufficiently and extend its service life,you must operate it according to the operating requirements,and what’s more,you must pay attention to necessary maintenance.Please read this section carefully and follow the execution to minimize the damage caused by the failure.

3.1 Announcements: (1). After machine running a period of time, if the oil seal wear exceeds the design standard, oil leakage will occur on the oil pump shaft, at this time, please change the O-ring in time according to 3). (2). After starting the machine, if there is abnormal vibration and noise, please handle the steps in the section of the troubleshooting section. (3). Before power on, please confirm that the voltage of the power supply should be confirmed to match the machine. (4). After turning on the power supply, normally the power indicator light is lit and alarm indicator light (differential pressure, phase sequence) & buzzer don’t work; if it is unnormal, please handle the steps in the section of the troubleshooting section. (5). Before starting the machine, please open the inlet and outlet ball valve.

3.2 Change elements: (1). Unscrew the vent plug, start the system; After the gas is expelled, screw the vent plug. (2). Insert the new filter element, press the small red pillar, clockwise tighten the cover. (3). Turn the handle of top cover counterclockwise, remove the cover, pull out the old filter element. (4). Firstly, power it down, close the inlet and outlet ball valve. Note: when you are changing the elements, please guarantee the cleanliness of filter & element, no dirt can come in.

3.3 Change oil pump seal: (1). Firstly, power it down, close the inlet and outlet ball valve. (2). Loosen the connection parts of inlet and outlet of oil pump. (3). Loosen the coonection part between the oil pump and cylinder flange, gently remove the oil pump. (4). Remove the coupling and connection keys from the oil pump shaft, remove the damaged fluorine rubber radial shaft seal, change a new one. (5). Install every part back.

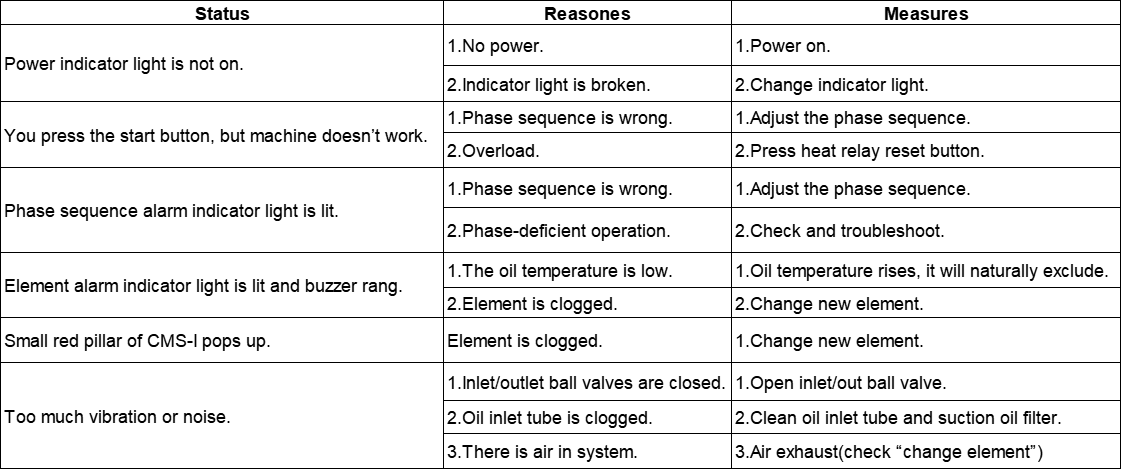

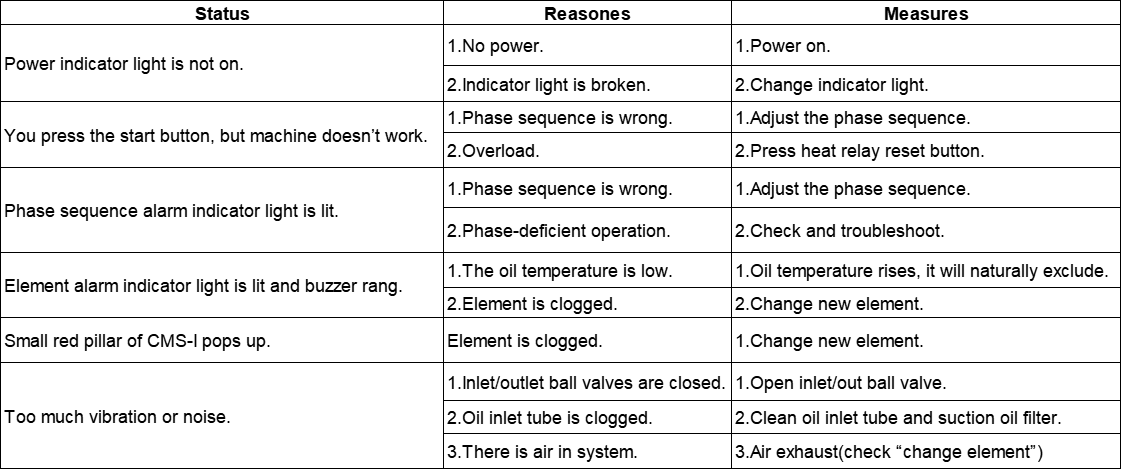

4.Fault treatment

Test standards:ISO 3724 Flow Fatigue CharacteristicsISO 16889 Multi-pass Performance TestingISO 2943 Material Compatibility with FluidsISO 3968 Pressure Drop vs. Flow RateISO 2942 Fabrication & Integrity TestISO 2941 Collapse & Burst Resistant

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration