|

Introduction: PD520 (2901-2004-10) is widely used together with air compressors and installed at the pipe after the air compressor.PD520 (2901-2004-10) atlas compressed air filters and pipeline gas filters are used to filter out impurities, liquid water, oil, and micro-oil mist in compressed air. All types of compatible filter elements comply with CE european standards and ISO international standards.Our company can provide filter elements compatible with compressed air filters of various domestic and foreign brands, which are compatible with original filter elements in terms of filtration performance and size.

Technical Data: | Flow rate(NM3/min) | Model No. |

|---|

| 0.54 | 009 | | 1.03 | 017 | | 1.92 | 032 | | 2.64 | 044 | | 3.6 | 060 | | 7.2 | 120 | | 9 | 150 | | 10.5 | 175 | | 15.6 | 260 | | 23.4 | 390 | | 31.2 | 520 |

| Series | Micron(um) | Oil Residue Component(ppm) |

|---|

| DD(DDP) | 1 | 1 | | PD | 0.01 | 0.01 | | QD | 0.01 | 0.003 |

Filter Material: We manufacture PD520 (2901-2004-10) compressor air filter with one or more layers of pleated media within a molded fiberglass laminate cylinder to provide greater particle filtration surface area. Pleats are kept open for full utilization using pleat corrugations and separation material. • Composite fiberglass and pleated media coalescers remove particles primarily from the high surface area pleated core. • All-fiberglass media coalescers combine deep particle filtration with a deep coalescing structure. • All-fiberglass designs have a continuous thinner dielectric layer for deep filtration of particles.

Quality Features: 1. Filtration accuracy: 0.01µm ~ 1µm 2. Filtration efficiency is 98% 3. PH range: 5 to 9 4. No media migration or “linting” 5. Maximum operating temperature:250°F. 6. The service life can reach about 3000h ~ 4500h 7. The filter material is made of American HV and Korean Ahlstrom pure wood pulp filter paper

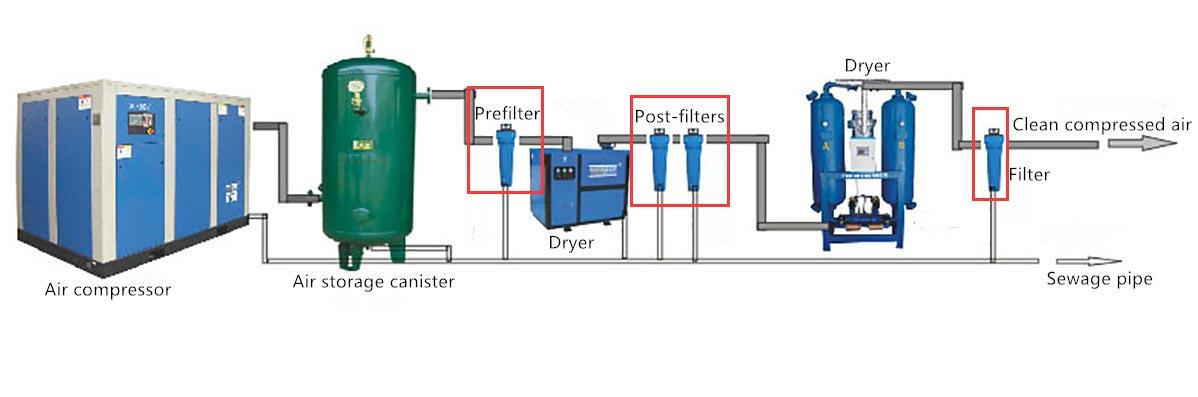

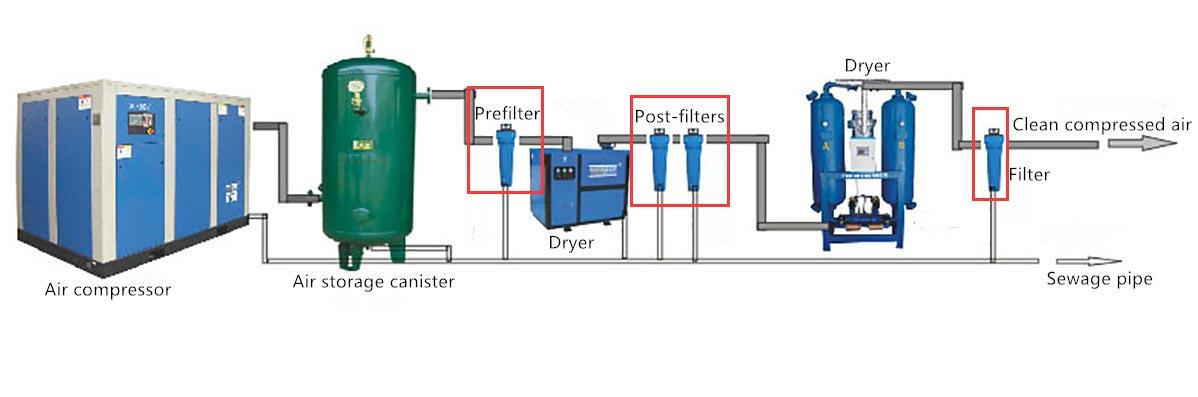

Working principle: PD520 (2901-2004-10) working principles is as below:

1. Diffusion deposition Because of Brownian motion,the movement of each fine particle is inconsistent with the flow direction of compressed air.With the decrease of particle size,the intensity of Brownian motion increases,the probability of collision between fine particles and fibers increases,and the diffusion and deposition become stronger.

2. Direct interception This mechanism is related to particle size.Particles are intercepted when the gap between the fibers is smaller than the particle diameter.

3. Inertial deposition The flow line bends as compressed air passes through the fiber.Because of inertia,particles in the compressed air do not travel along the curved streamlines,but instead are flung onto the fibers and deposited there.Obviously,this inertial effect is enhanced with increasing air mass by increasing particle size and compressed air flow.

4. Gravitational sedimentation Due to the action of gravity,all kinds of particles have a certain velocity of settlement.As a result,the trajectory of the particles deviates from the streamlines of the compressed air,and this deviation causes the particles to strike the fibers.

5. Electrostatic deposition Both particles and fibers may be charged,so particles are deposited on the fibers by force or induction between electric charges.

6. Van der Waals deposition When the distance between particles and fibers is small,van der Waals forces between molecules cause particle deposition.Due to the simultaneous action of the above filtration mechanisms,the filtration efficiency of the fiber filter can reach more than 99%.

Support Customization: Our company also offers a full range of replacement filter elements. They meet quality requirements and can be installed in the following products: ATLAS COPCO INGERSOLL RAND HANKISON DOMNICK HUNTER HIROSS ZANDER ORION JM PALL ULTRAFILER SMC BEA Other types are available on request

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration