|

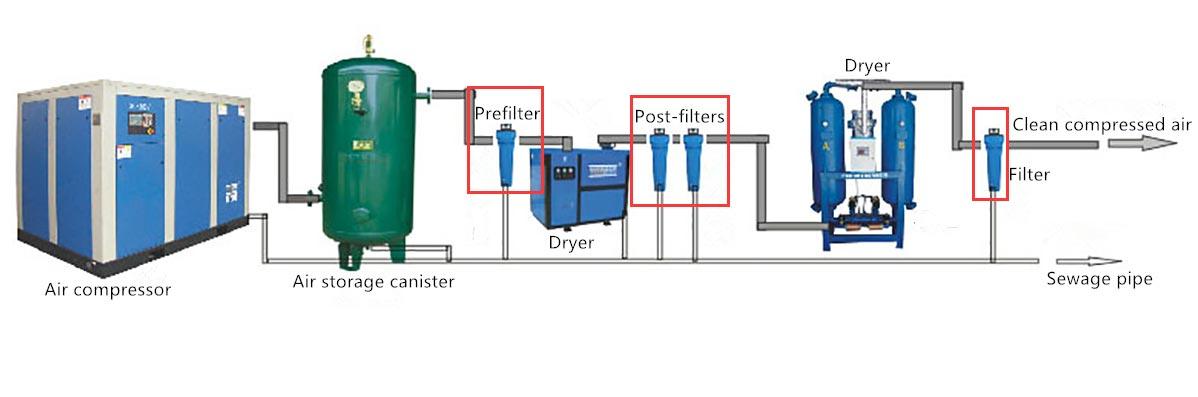

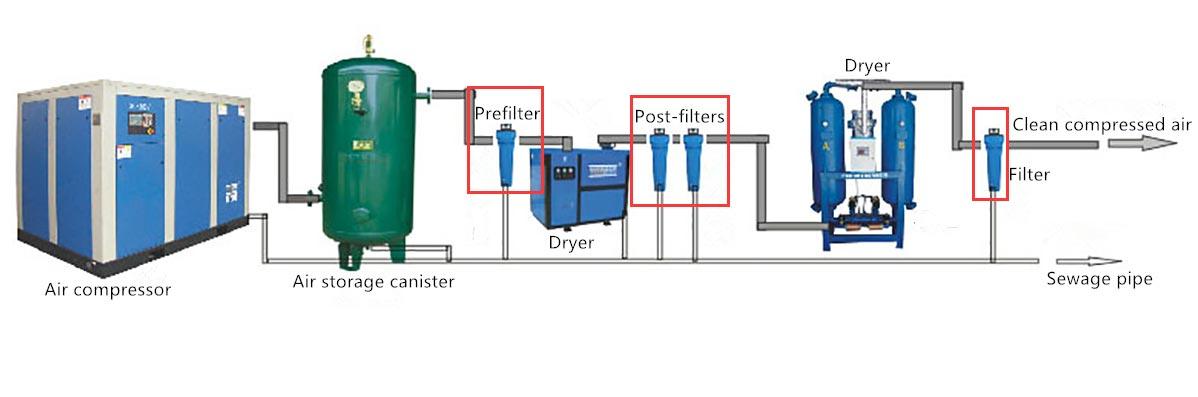

Introduction: 3050A is used to remove water,oil vapor and other contaminants from a compressed air line,providing the highest level of clean compressed air with a minimum loss of pressure.Our coalescing filter elements are tough enough to hold their shape under pressure and maintain even pressure differentials to avoid collapsing of the filter element.

More Related Filters: CP1008VL CP2010ZL CP2020XL CP3025A CP3040XL CP4050ZL CP5065VL CP5080ZL CP5065A

Additional Notes: 3050A Zander replacement compressed air filter element is produced with the highest quality materials and workmanship.This coalescing filter element offers equal to or better filtration performance based on the original OEM filter specifications.

Zander Replacement Filter Technical Datas: | Flow rate(nm3/min) | Model |

|---|

| 0.5 | 1030............ | | 0.85 | 1050 | | 1.2 | 1070 | | 1.7 | 1140 | | 3 | 2010 | | 5 | 2020 | | 7.8 | 2030 | | 11.7 | 2050 | | 16 | 3050 | | 24 | 3075 |

| Series | Micron(μm) | Oil Residue Component(ppm) |

|---|

| V | 3 | 5 | | Z | 1 | 0.5 | | Y | 0.1 | 0.1 | | X | 0.01 | 0.01 | | A | 0.01 | 0.003 |

Quality Features: 1. Filtration accuracy: 0.01µm ~ 1µm 2. Filtration efficiency is 98% 3. PH range: 5 to 9 4. No media migration or “linting” 5. Maximum operating temperature:250°F 6. The service life can reach about 3000h ~ 4500h 7. The filter material is made of American HV and Korean Ahlstrom pure wood pulp filter paper

Filter Material: We manufacture 3050A compressor air filter with one or more layers of pleated media within a molded fiberglass laminate cylinder to provide greater particle filtration surface area. Pleats are kept open for full utilization using pleat corrugations and separation material. • Composite fiberglass and pleated media coalescers remove particles primarily from the high surface area pleated core. • All-fiberglass media coalescers combine deep particle filtration with a deep coalescing structure. • All-fiberglass designs have a continuous thinner dielectric layer for deep filtration of particles.

Performance Features: 1. Air permeability The filter element adopts American fiber filter material with strong hydrophobicity and oil repellency,and at the same time adopts a framework with good permeability and high strength to reduce the resistance caused by filtration.

2. High Efficiency The filter element adopts German fine open-pore sponge,which can effectively prevent oil and water from being entrained by high-speed airflow,so that the filtered fine oil droplets gather at the lower end of the filter element sponge and drain to the bottom of the filter container.

3. Airtightness The joint between the filter element and the filter housing adopts a reliable sealing ring to ensure that the airflow is not short-circuited and prevent impurities from directly entering the downstream without passing through the filter element.

4. Anti-corrosion The filter element adopts anti-corrosion reinforced nylon end cover and anti-corrosion filter frame,which can be used in harsh working conditions.

Support Customization: We can provide filter elements compatible with various foreign and domestic brands of compressed air filters,including: Hankison Dominck Hunter Ulrafiter Hiross SMC Orion Zander Bea Parker Atlas Copco Technolab JM MANN Other types are available on request

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration