|

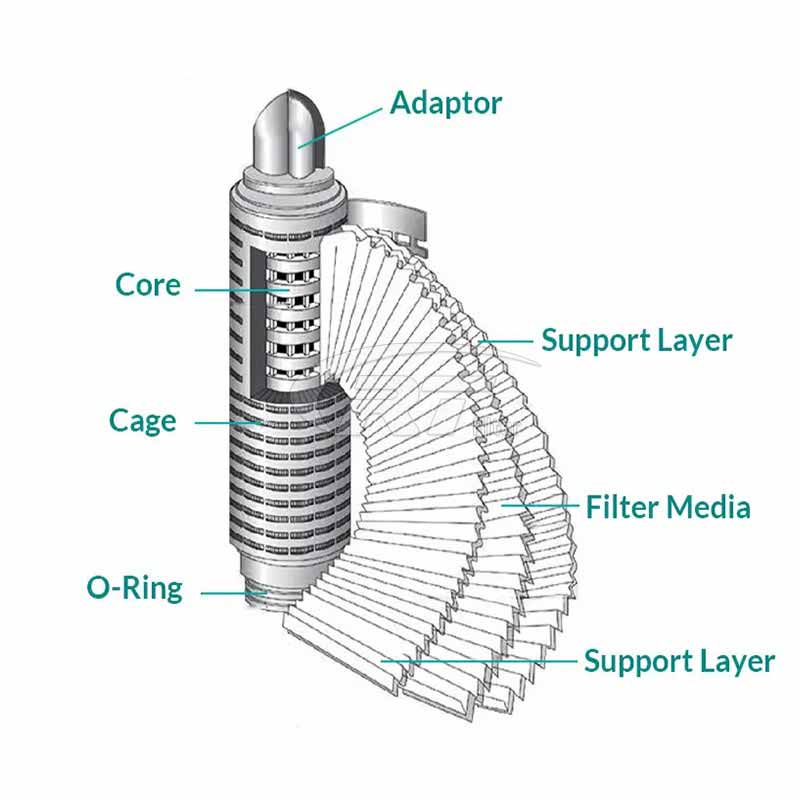

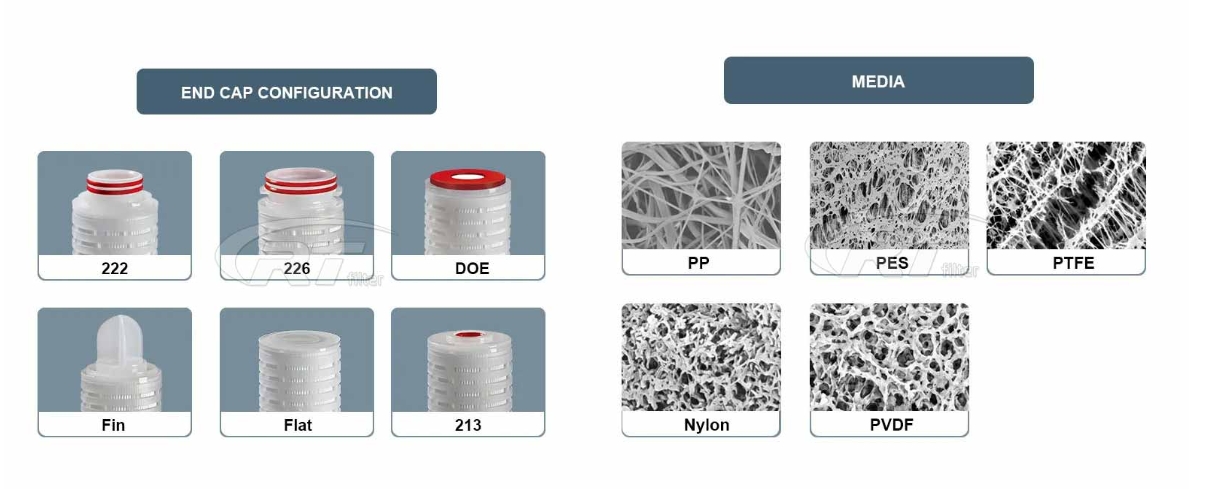

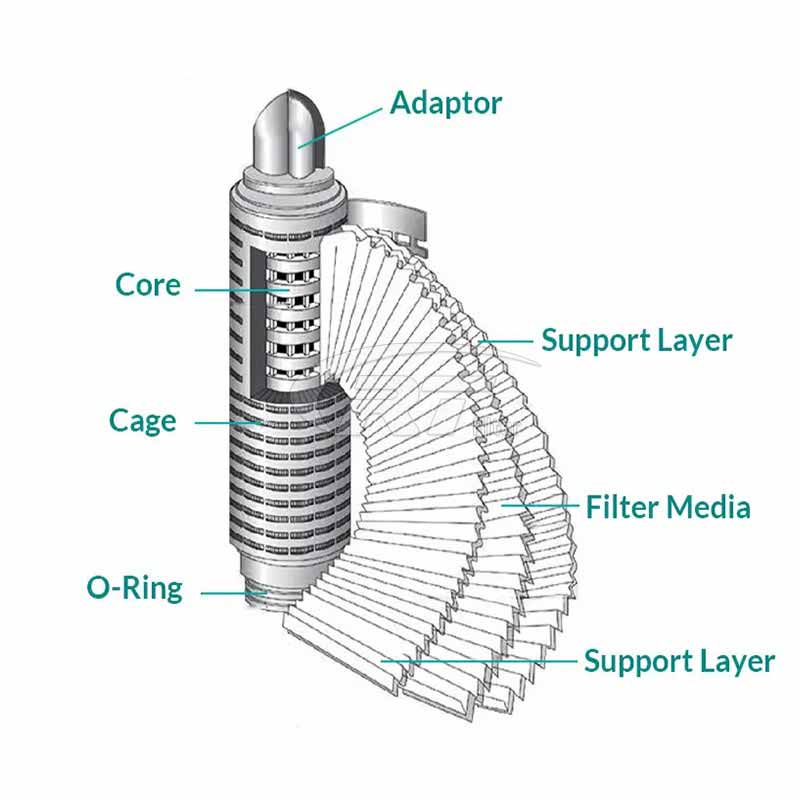

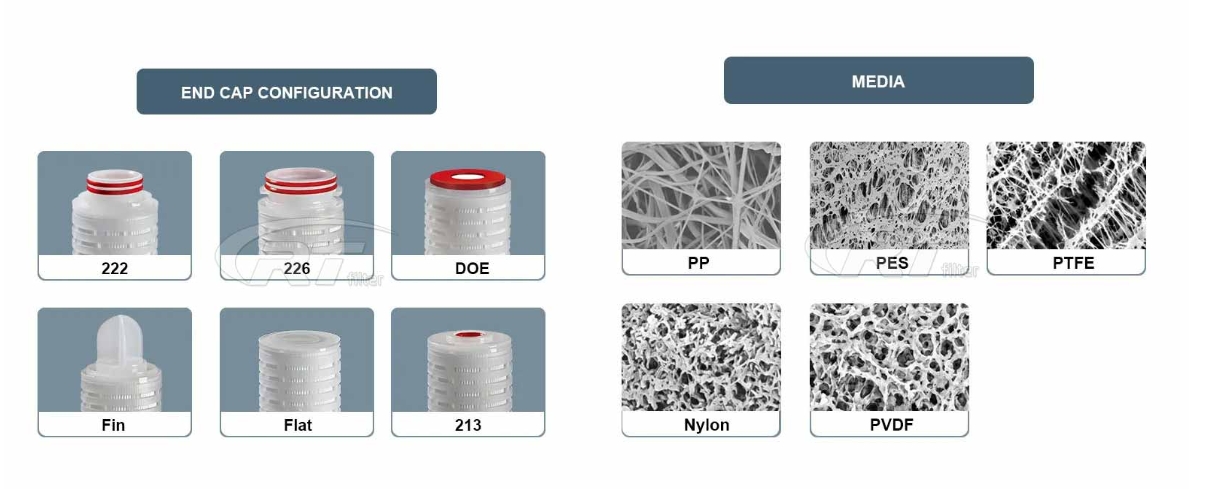

Brief Introduction: Microporous pleated membrane cartridges are constructed of high-quality membranes and polypropylene support layers and components.Membrane cartridges are 100% integrity tested during production with full batch material traceability.Manufactured,rinsed,tested and packaged in a clean room,membrane filter elements are engineered for maximum throughput and high dirt-holding capacity through broad chemical compatibility,large surface area for consistent filtration efficiency and high flow rates. Advanced membrane materials include nylon,PTFE,PES,glass fiber,PVDF,etc.,which can meet water treatment,food and beverage,pharmaceutical filtration,solvent,semiconductor,cosmetics,bottled water and many key industries.

Features: (1). The material meets FDA requirements. (2). Provide a variety of filtering precision. (3). The membrane is deeply folded and filtered, and the folded design increases the filtration area. (4). Gradual pore size change can provide high dirt-holding capacity. (5). Excellent chemical compatibility, suitable for filtering strong acids, strong alkalis and organic solvents. (6). Low PSID (Pounds per Square lnch Differential), strong dirt holding capacity and long service life.

Filter element sizes: Outer Diameter: 69mm Length: 9.75″, 10″, 20″, 30″, 40″

Materials: Sealing ring material:silicone rubber,ethylene propylene rubber,nitrile rubber,fluorine rubber,Teflon rubber. Outer/Inner Supports/End Caps:Polypropylene. Support/distribution layer:Polypropylene. Filter material:polypropylene(PP),polyethersulfone(PES),polytetrafluoroethylene(PTFE),nylon 6(N6), PVDF membrane

Performance Features: Maximum back pressure difference:2.0 Bar at room temperature.Sterilization temperature:121°C,30 minutes each time. Maximum differential pressure:4.0bar at room temperature. Filtration:0.1µm,0.22µm,0.45µm,1µm,3µm,5µm,10µm,20µm,50µm. Maximum operating temperature:1 bar 80°C (when the temperature exceeds 50°C, it is recommended to use stainless steel as a support).

Additional Notes: We manufacture kinds of microporous pleated water filter elements,they are made of a variety of high-quality filter materials,and the pleated filter element is made of imported non-woven fabric or mesh cloth as a support layer.Materials comply with FDA requirements and have a wide range of chemical compatibility.The filter housing,center rod,and end cap adopt hot-melt welding process without using any glue,and the production process is environmentally friendly,pollution-free,and leak-free.

Applications: Pharmaceutical industry:pre-filtration of various antibiotics and other liquid medicines Food and beverage industry:filtration of wine,mineral water and drinking water Petroleum Industry:Oilfield Water Injection Filtration Electronics industry:high-purity water pre-filtration Chemical industry:Filtration of various organic solvents,acids and lyes

Our factory also offers a full range of replacement filter elements: Parker 3M Pentair Peco Other types are available on request

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration