|

Introduction: 3M large-flow industrial water filters are used to clean and filter water fluids, and effectively remove impurities such as tiny particles and bacteria in the water fluids. The 3M industrial water filters filtration efficiency is as high as 99.8%, ensuring the original quality attributes of the water fluids. It is a high-efficiency microporous pleated water filter type.

More Related Filters: RSCP010-20NPP RSMG008-40NPP RSCP030-60NPP RSMG030-40NPP RSCP100-20NPP RSCP900-60NPP RSMG010-60NPP RSCP900-20NPP RSMG200-60NPP

Filter material is as follows: 3M large-flow industrial water filters structure adopts multi-layer stepped folding w-pleated corrugated shape UP media technology design to achieve the maximum processing capacity of pollutants and excellent pollutant absorption capacity and interception efficiency, ensuring that the required filtration cleaning standards are met. The 3M water filters material complies with FDA requirements, has strong mechanical strength and extensive chemical resistance, and is suitable for various filtration scenarios. ...

Technical specifications: • Filter Material: Pleated Fiberglass, Pleated Deep Polypropylene (PP), MBPP • Maximum pressure drop: pleated fiberglass--4.0bar, pleated deep polypropylene (PP)--3.4bar, MBPP--1.03bar • Maximum temperature: wrinkled fiberglass--121℃, deeply wrinkled polypropylene (PP)--82℃, MBPP 65℃ • Support/Diversion Layer: Polypropylene (PP) • Sealing material: EPDM, BNR • End cap: fiberglass reinforced polypropylene • Center pole: polypropylene • Filtration precision: 0.1μm, 0.22μm, 0.45μm, 1μm, 3μm, 5μm, 10μm, 20μm, 50μm. • Filter element surface: PP melt-blown, melt-blown fine lines, melt-blown grooves, melt-blown embossing • Gasket: silicone rubber, ethylene propylene rubber, nitrile rubber, fluorine rubber • Recommended maximum filtered water flow rate: 660L/min for 20-inch filter, 1300L/min for 40-inch filter, 1900L/min for 60-inch filter

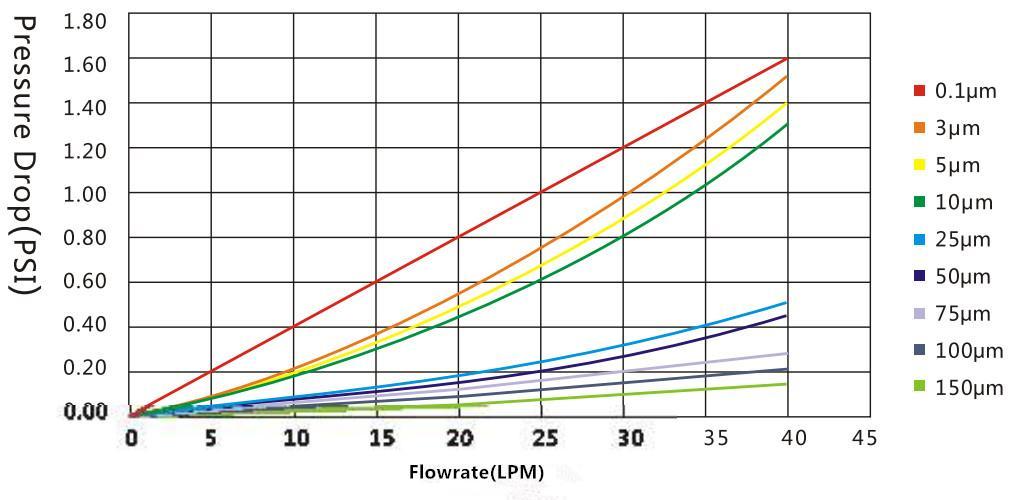

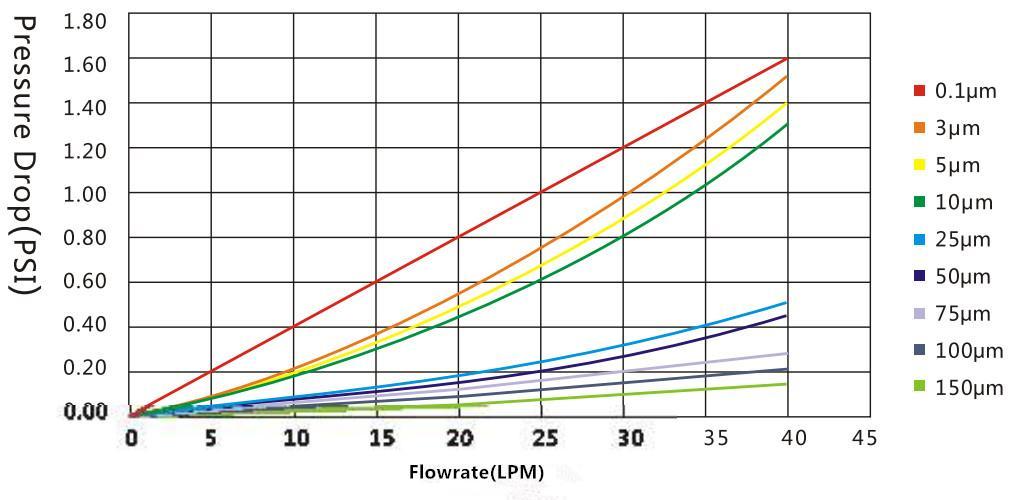

The flow characteristics of PP material are as shown in the figure: 3M large-flow industrial water filters manufacturing materials are made of high-quality, safe and environmentally friendly filter membranes, and imported non-woven fabrics or mesh fabrics are used as the support layer, with full batch material traceability. The filter housing, center rod, and end caps adopt hot-melt welding technology without using any adhesives, additives, or lubricants, and without any fiber shedding. The production process is environmentally friendly, pollution-free and leak-free. 100% integrity tested during production, manufactured, rinsed, tested and packaged in a clean room. ....

Main features: • High throughput cleaning of fluids can be achieved in a single filter element. • 100% PP high-quality filter material, high corrosion resistance. • Meets customized customization of various filtration precisions to ensure different precision level requirements. • Made of PP microfiber with high filtration accuracy. • High-quality filter media combined with internal multi-layered pleated depth filtration. • High-quality filter material and hot-melt bonding process, high cleanliness, no adhesive added, no pollution to water quality. • Deep groove folding design increases the filtration area and the pressure drop is significantly lower than ordinary filter elements • Large diameter design increases the anti-fouling properties of the filter element, prolongs service life and reduces usage costs.

Our factory also offers a full range of replacement filter elements: Parker 3M Pentair Peco

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration