|

Introduction: Pleated Polypropylene(PP) Water Treatment RO Filter Cartridge is used to clean and filter water fluids and effectively remove impurities such as tiny particles and bacteria in the water fluids. The filtration efficiency is as high as 99.8%, ensuring the original quality attributes of the water fluids. It is a high-efficiency microporous pleated water filter type.

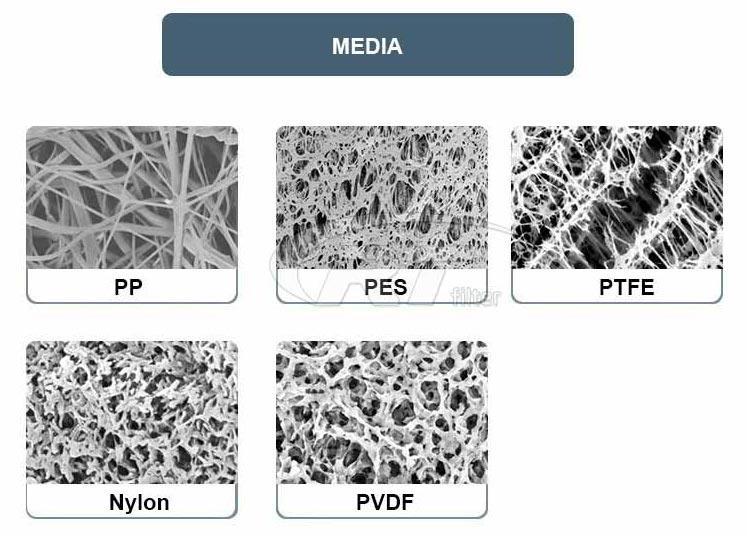

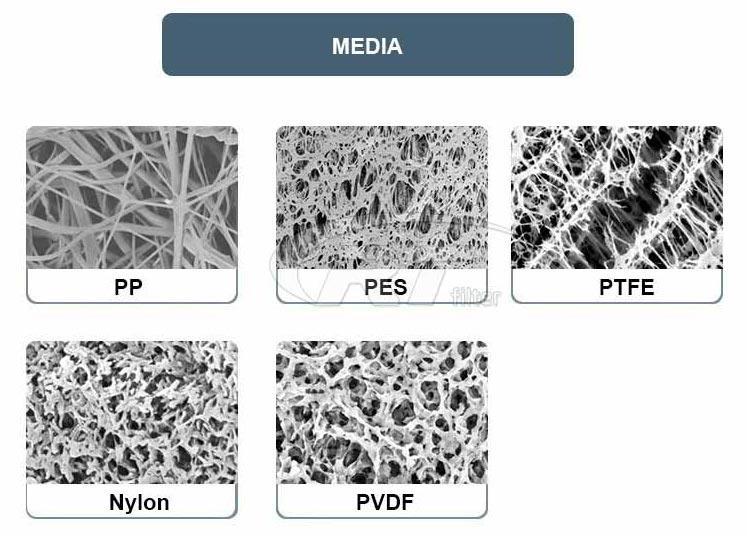

Core Filter Material: Pleated Polypropylene(PP) Water Treatment RO Filter Cartridge manufacturing materials are made of high-quality, safe and environmentally friendly filter membranes, and imported non-woven fabrics or mesh fabrics are used as the support layer, with full batch material traceability. The filter housing, center rod, and end caps adopt hot-melt welding technology without using any adhesives, additives, or lubricants, and without any fiber shedding.

......

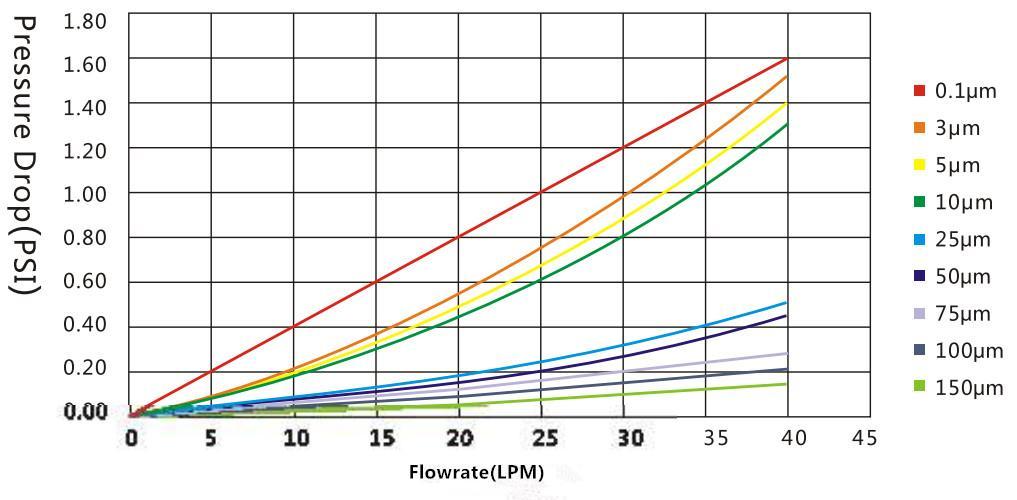

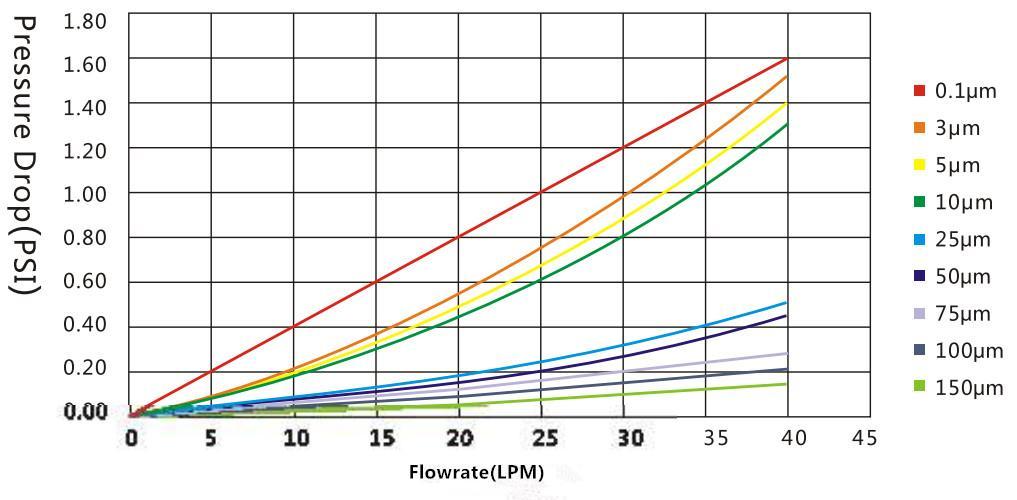

Technical specifications: • Filter Material: Pleated Fiberglass, Pleated Deep Polypropylene (PP), MBPP • Maximum pressure drop: pleated fiberglass--4.0bar, pleated deep polypropylene (PP)--3.4bar, MBPP--1.03bar • Maximum temperature: wrinkled fiberglass--121℃, deeply wrinkled polypropylene (PP)--82℃, MBPP 65℃ • Support/Diversion Layer: Polypropylene (PP) • Sealing material: EPDM, BNR • End cap: fiberglass reinforced polypropylene • Center pole: polypropylene • Filtration precision: 0.1μm, 0.22μm, 0.45μm, 1μm, 3μm, 5μm, 10μm, 20μm, 50μm. • Filter element surface: PP melt-blown, melt-blown fine lines, melt-blown grooves, melt-blown embossing • Gasket: silicone rubber, ethylene propylene rubber, nitrile rubber, fluorine rubber • Recommended maximum filtered water flow rate: 660L/min for 20-inch filter, 1300L/min for 40-inch filter, 1900L/min for 60-inch filter

The flow characteristics of PP material are as follows: The production process is environmentally friendly, pollution-free and leak-free. 100% integrity tested during production, manufactured, rinsed, tested and packaged in a clean room.......

Application areas: • Painting and petrochemical industry • Filtration of raw materials, solvents and water in biopharmaceutical industry • RO cartridge filtration and seawater desalination pretreatment • Microelectronics, films, fibers, resins • Power plant condensate water filtration • Filtration of bottled water, liquid glucose, edible oil, juice, soft drinks, milk

Our factory also offers a full range of replacement filter elements: Parker 3M Pentair Peco

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration