|

Brief Introduction: Our factory makes kinds of filter housing,the WU-100X80J filter is rough hydraulic filter housing and can be installed at the inlet of the pump and can protect the pump not to in breathe the bigger impurity.The filter is simple designed. It's easy to let oil go through and it has small resistance. It also has threaded connection and flanged connection. This kind of filter can be divided into wire mesh filter and notched wire filter,WU and XU series.

Performance characteristics: 1. The oil filter is easy to install and connect, simplifying the system pipeline; 2. Set the self-sealing valve, which makes it very convenient to replace, clean the filter element or maintain the system; 3. Equipped with a filter element pollution transmitter and an oil bypass valve, which improves the reliability of the hydraulic system.

Applications: 1. In the machine tool industry,85% of the current machine tool transmission systems use hydraulic transmission and control.Such as grinding machines,milling machines,planers,broaching machines,presses,shearing machines,and combined machine tools,etc. 2. In the metallurgical industry,hydraulic technology is used in electric furnace control systems, rolling mill control systems,open hearth furnace charging,converter control,blast furnace control,strip deviation and constant tension devices. 3. In construction machinery,hydraulic transmission is widely used,such as excavators,tire loaders,truck cranes,crawler bulldozers,tire cranes,self-propelled scrapers,graders and vibratory rollers. 4. In agricultural machinery, hydraulic technology is also widely used,such as combine harvesters,tractors and plows. 5. In the automobile industry,hydraulic off-road vehicles,hydraulic dump trucks,hydraulic aerial work vehicles and fire trucks all use hydraulic technology. 6. In the textile industry, hydraulic technology is used in plastic injection molding machines,rubber vulcanizing machines,paper machines, printing machines and textile machines.

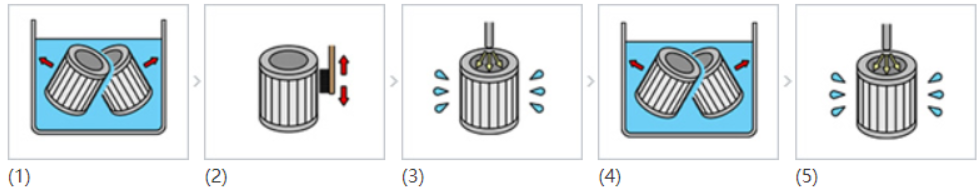

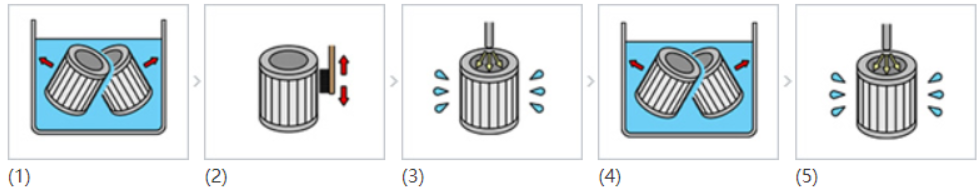

Filter Cleaning: The WU-100X80J is made of stainless steel mesh material,it can be cleaned again after use.However,only a certain cleaning level (percentage) can be achieved.For best results,components should be cleaned using professional equipment.But cleaning results are unpredictable.It depends a lot on various conditions  | (1) Dip the filterelement in light oil and rotate thoroughly. | (2)Clean off dirt by scrubbing the element with a brush parallel to the pleats. | (3)Clean off dirt with an air spray gun. | (4)Rinse well. | (5)Dry using an air spray gun. |

Test standards: ISO 2941 Collapse & Burst Resistant ISO 2942 Fabrication & Integrity Test ISO 2943 Material Compatibility with Fluids ISO 3724 Flow Fatigue Characteristics ISO 3968 Pressure Drop vs. Flow Rate ISO 16889 Multi-pass Performance Testing

Our factory also offers a full range of replacement filter elements. They meet quality requirements and can be installed in the following products: ARGO,DONALDSON,EPPENSTEINER,FILTREC,HYDAC,HY-PRO INTERNORMEN,LEMMIN,MANN,MAHLE,MP-FILTRI,PARKER REXORTH,STAUFF,TAISEI KOGYO ,VICKERS Other types are available on request

|

Air Compressor Filtration

Air Compressor Filtration

Equipment Oil Pollution Filtration

Equipment Oil Pollution Filtration